One of the truest joys of any craftsman is to build an exquisite toolbox. This is true for physical crafts such as carpentry, masonry, and mechanics as well as soft crafts like painting and dancing.

Confident that you have all the equipment and knowledge to do the work makes all projects easier. Of course, gaining that toolbox comes first. When it comes to buying garage tools you get to think big but resources are never limitless.

Tools still indeed to be considered in terms of money, space, and optimal use. With those parameters in mind, check out these factors for buying tools online or offline.

Buying Garage Tools?

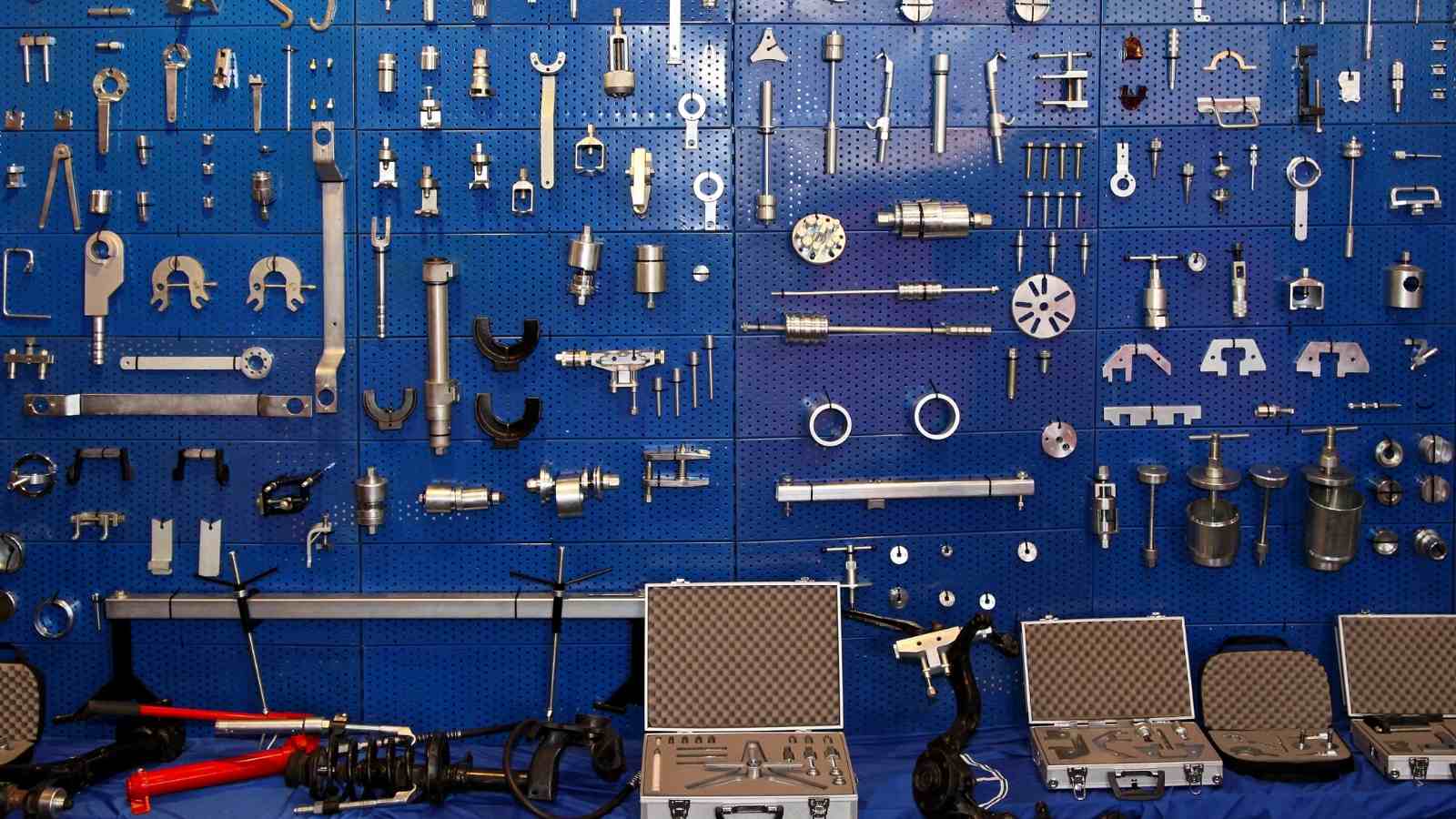

As the intro points out, having a toolbox is good. having a whole tool room is better. Getting the right equipment up front saves money over time and provides a more solid foundation for building into an expertise.

The economy of scale says it's still best to start with the basics and expand to meet needs. These tips are built around that concept.

1. Basics

You want to start with a list of the basic tools needed to get a job done. This isn't about rustic practices for building up aptitude, it is about understanding offerings.

All modern tools do what older tools did but faster, easier, and hopefully safer. Knowing how a tool functions in its most basic form gives you the ability to understand what options on a deluxe tool are useful for your projects and which are fluff.

It's also handy to have a full set of practical hand tools for repairing any of your mechanical and powered gear.

2. Reliability

Next, you want to consider which tools have the best ratings for reliability and warranty. Replacing a drill every year because the old one has burned out, again, puts a dent in other budgets.

Tools need to resist more than time and use. They also need to be resistant to brute damage, acids, oils, and other environmental hazards that come with your craft.

When it comes to hardness, different metals react more favorably to wear than others. Hard tools resist corrosion and do a better job avoiding wear when coming into contact with other parts. The last thing you want is a super hard tool that chips or shatters at sub-optimal temperatures.

3. Power Variations

Outside of hand tools, there're further differences between low and high-powered tools. Industrial strength machinery is good in some places where finesse is superior in others.

If you are buying an air compressor, bigger isn't usually overkill as you can adjust to your needs. Buying an underpowered pneumatic wrench or arc welder is going to be a headache.

For hammers, drills, drill presses, and the like, you want to consider the damage they can do when exerting too much force. Artisinal square head bolts make great finishes for crafts, but if you hit them too hard you'll damage their unique finishes.

Remember also that power tools cost money over time to operate. check out the Energy Star ratings and keep in mind your end-of-month costs for each piece of equipment.

4. Safety

Even the best quality tools that do exactly what you want will vary in terms of safety. Do they have anti-slip grips, shockproof coatings, textured handles that maximize leverage?

Ergonomically shaped tools sound like an extravagance early on, but work it for ten years and your hands, wrists, and back will notice the difference. Fatigue in terms of grip span leads to repeated use injury but also increases the risk of snapping other parts.

It's difficult to gauge how much pressure you're applying with pliers, tin snips, and the like if you're always two-handing them for power.

For larger table equipment you want auto-shut offs and fire-retardant materials that will help you avoid catastrophe.

5. Budget

You can't buy what you can't afford. This could be seen as a first-tier concern but quite frankly it only really matters on a per-purchase basis. It is better to consider all the factors that go into tool purchases upfront and then scale down what you buy, not the quality of what you buy.

Ideally, each purchase can be the last if you buy the right thing. You don't want to go out comparing tool costs without context for prices.

To this end, budget in terms of the basics to get started and then consider how much you need to save to hit your next tier. With a proper map, you will be able to equip your garage workbench fully before you start replacing anything.

For hobbyists, the budget constraints are about interest, so less is more. For business purposes, the budget to expand is based on the money coming in, so always leave a margin for replacements to keep working.

6. Multi-Tasking

As you reconsider a starting budget, look at what tools best serve multiple purposes. While having a dedicated tool for each task ensures higher-quality work and less overall wear and tear, there's a certain joy in jerry-rigging for results.

Watch any vehicle modification show and you'll see a grinder used for every other type of tool at least once. A good Dremel will help in much the same way.

It's always possible to rent a tool from a local hardware shop if you need something specific that you don't have. This is also a good way to test-drive a few tools to increase your knowledge base and make decisions on what you can and can't live without.

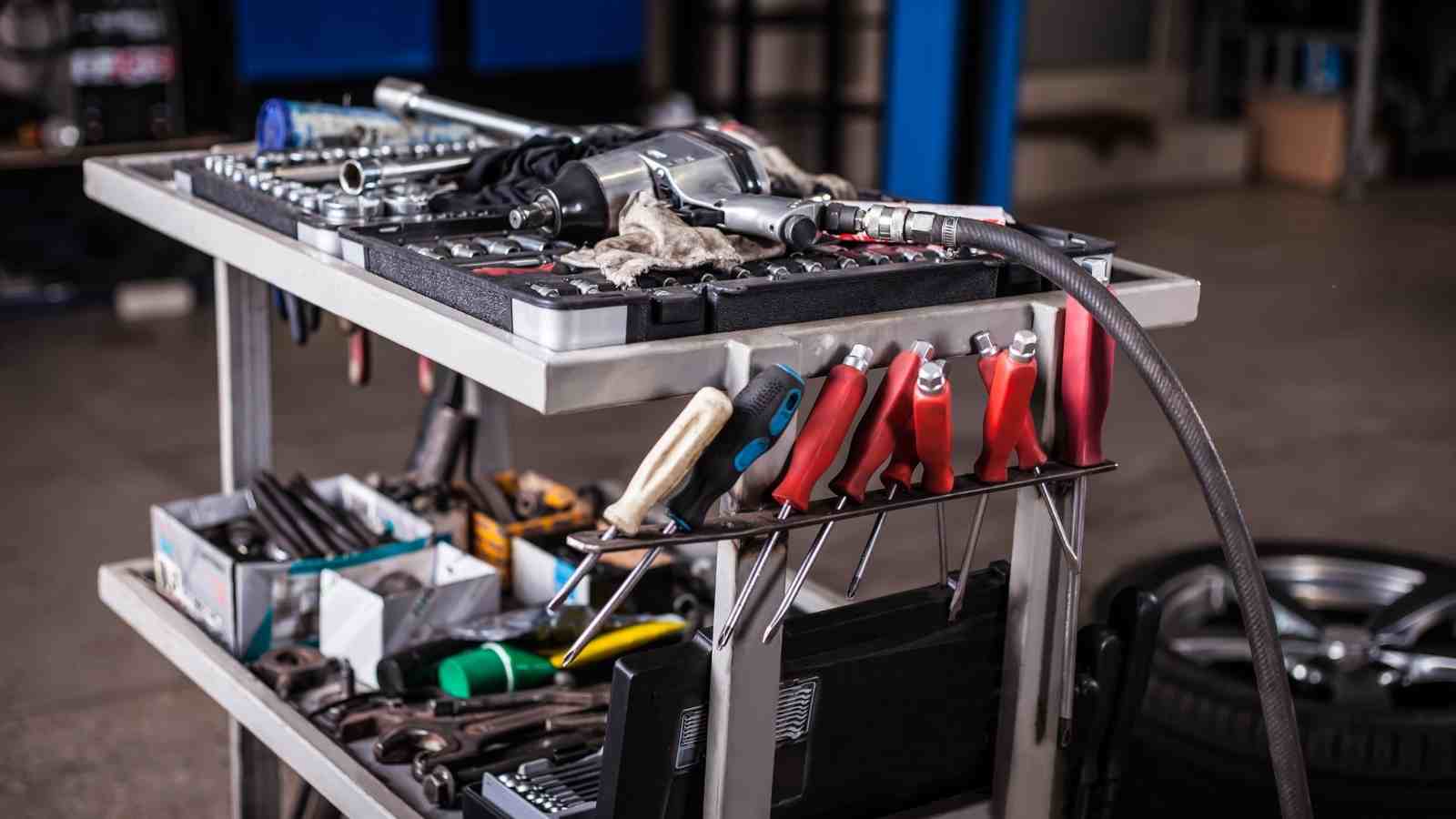

7. Working Space

Finally, consider the size of your garage and the space you have for working. If you fill your workspace with tools, you won't have any workspace.

Workable space reduces the risk of injury and damage. Slamming your hand into the wall or banging your head on a low ceiling are constant threats when working in tight corners.

If you work with welding, painting, sanding, or stripping agents you also want enough ventilation to negate combustion and breathing hazards.

More DIY

With so many options in tools these days, you need to hammer down a plan before buying garage tools.

Above all else, remember that what you need is what you need and should take priority. Availability isn't universal and the tool you have beats the one you wish you had.

Enjoy this article? Then come back here for more DIY and craft tips.